About Us

Conover Plastics is a privately held plastic injection molding company located in a

modern facility in Conover, North Carolina.

We were founded in 1974 to serve the hosiery industry with injection molded hangers. Today we are the largest sock hanger manufacturer in the U.S. In addition to being the premier injection molding specialists for the hosiery industry, we provide custom products for the Furniture, Textile, Packaging, and Toy industries. We are seen as one of the best plastic injection molding companies in the industry.

We are innovators and solution providers and take a great deal of pride in that

fact.

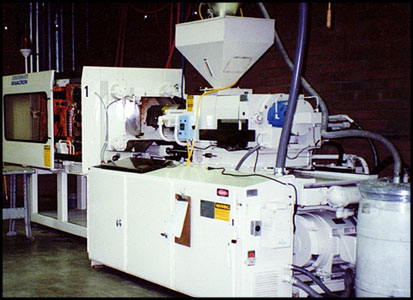

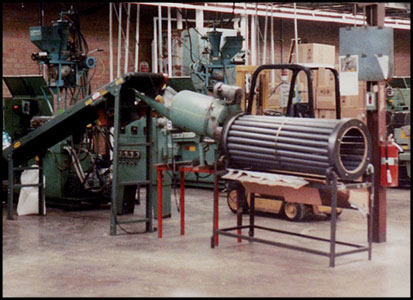

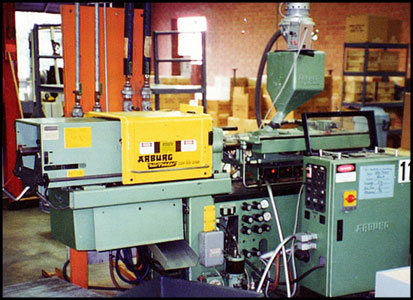

Our most recent patented products include the Water Fall Hangers Series and the Toe Catcher Series. These patented products provided a superior product presentation and display. Our injection molding machines are made by Cincinnati Milacron’, Van Dorn’, and HPM’ and are between 75 and 500 tons with shot weights between 5 to 35 ounces. Most other plastic injection molding companies don’t have this capacity. Their facilities usually can’t handle these requirements.

You may be wondering…why work with a North Carolina based manufacturer?

Our low cost of living, which includes our employee wages, energy and workers compensation cost means you save too. We pass these reduced costs right on to our customers. Plus, the state and local government make it very easy for manufacturers like us to do business. As injection molding specialists, it’s nice to operate in this environment. In addition, our plastic injection molding facilities are state of the art.

Conover Plastics is a privately held plastic injection molding company located in a

modern facility in Conover, North Carolina.

We were founded in 1974 to serve the hosiery industry with injection molded hangers. Today we are the largest sock hanger manufacturer in the U.S. In addition to being the premier injection molding specialists for the hosiery industry, we provide custom products for the Furniture, Textile, Packaging, and Toy industries. We are seen as one of the best plastic injection molding companies in the industry.

We are innovators and solution providers and take a great deal of pride in that

fact.

Our most recent patented products include the Water Fall Hangers Series and the Toe Catcher Series. These patented products provided a superior product presentation and display. Our injection molding machines are made by Cincinnati Milacron’, Van Dorn’, and HPM’ and are between 75 and 500 tons with shot weights between 5 to 35 ounces. Most other plastic injection molding companies don’t have this capacity. Their facilities usually can’t handle these requirements.

You may be wondering…why work with a North Carolina based manufacturer?

Our low cost of living, which includes our employee wages, energy and workers compensation cost means you save too. We pass these reduced costs right on to our customers. Plus, the state and local government make it very easy for manufacturers like us to do business. As injection molding specialists, it’s nice to operate in this environment. In addition, our plastic injection molding facilities are state of the art.

About our Team

Sal Hazboun

President

- Mr. Hazboun holds a BS degree in engineering from California State Polytechnic University and a MBA with an emphasis in Operational Management & Logistics and Management of Innovation & Technology.

- All of Mr. Hazboun’s experience has been in the plastics industry and includes Packaging Engineering, Quality Manager, Production Manager, Plant Manager, Director of Manufacturing, Commercial Director, and General Manager and Vice President.

- Mr. Hazboun experience as an injection molding specialist includes working for Fortune 500 companies and smaller companies.

- Processes managed includes: plastic injection molding, blow molding, blown film extrusion, lamination, thermoforming, and rotational molding.

- Currently presides over one of the best plastic injection molding companies in the industry!

Mary Canavati-Hazboun

Vice President

- Ms. Canavati has a diverse background in international manufacturing & sales, interior design of commercial, residential, and religious institutions, and retail.

- As a General Manager of Camas Dina-Honduras, Ms. Hazboun managed several aspects of the daily operations of the mattress manufacturing factory, designed mattress patterns and support systems for improved comfort, in addition to help increase sales Serta mattress in Central America.

- Additionally, Ms. Hazboun has managed premium retail stores and was instrumental in double digit growth of revenue.

- Ms. Hazboun design experience includes award winning interior and exterior designs for high profile residental properties, the exterior elevation of the facade for a prestige architectural firm, and the passageways for the church of San Juan Iglesia Orthodox church.

- Ms. Hazboun obtained her Bachelor of Science in Interior Design with a minor in Architecture from Philadelphia Collage of Textile and Science.

Our Mission

As the “Customers Choice for Design and Molding”, we:

- SAFELY and TIMELY provide QUALITY products and services the first time and every time and provide the very BEST VALUE.

- Never take our customers for granted; we earn their business every day, and continually enhance our value in their eyes.

- Challenge ourselves as injection molding specialists and constantly check our prectices to improve our preformance and grow our business.

- Focus on being good citizens in our community

- Treat all employees, customers, and vendors ethically and fairly.

- Lead the other plastic injection molding companies in the industry by good example

Contact Us

Discover how our plastic injection molding facilities can provide you with the exact product you need.